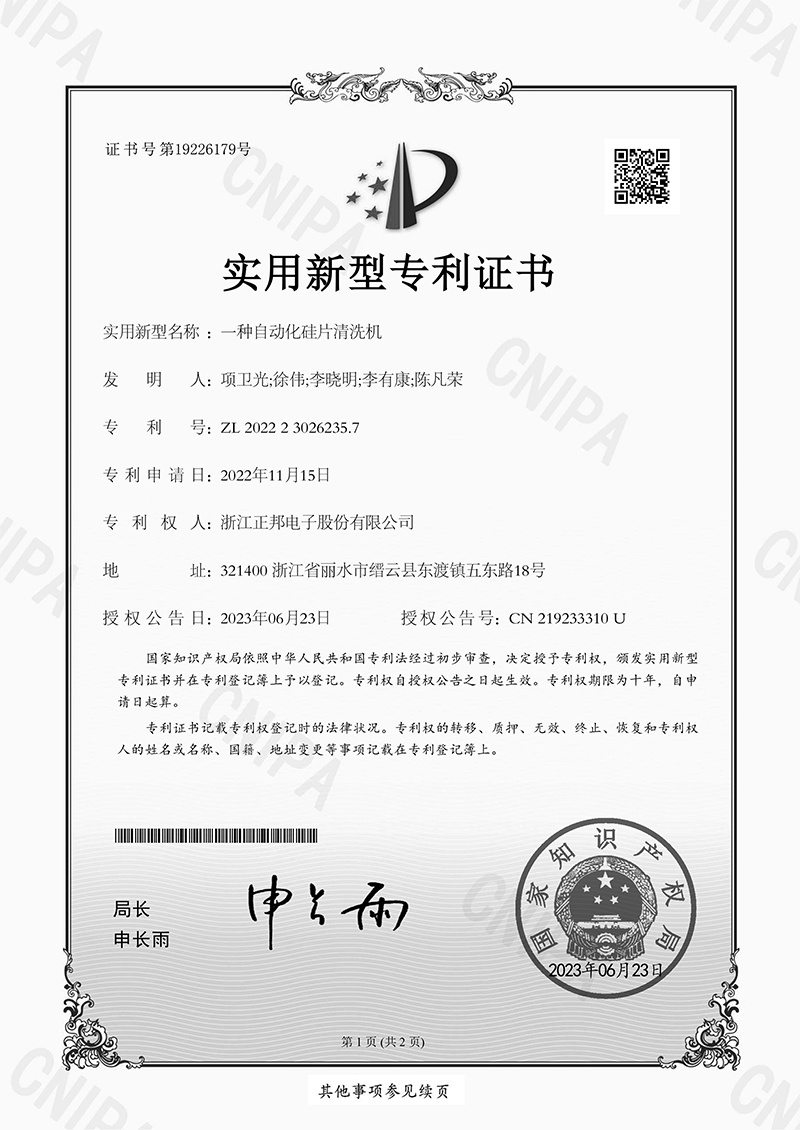

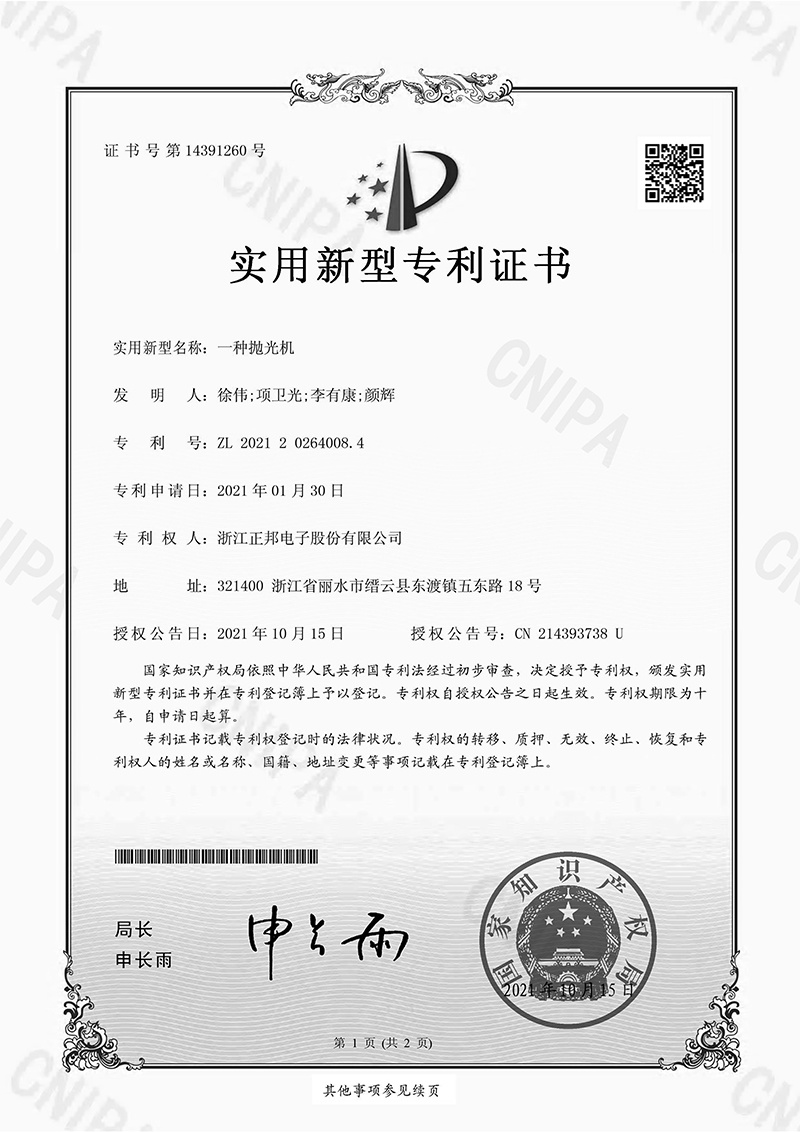

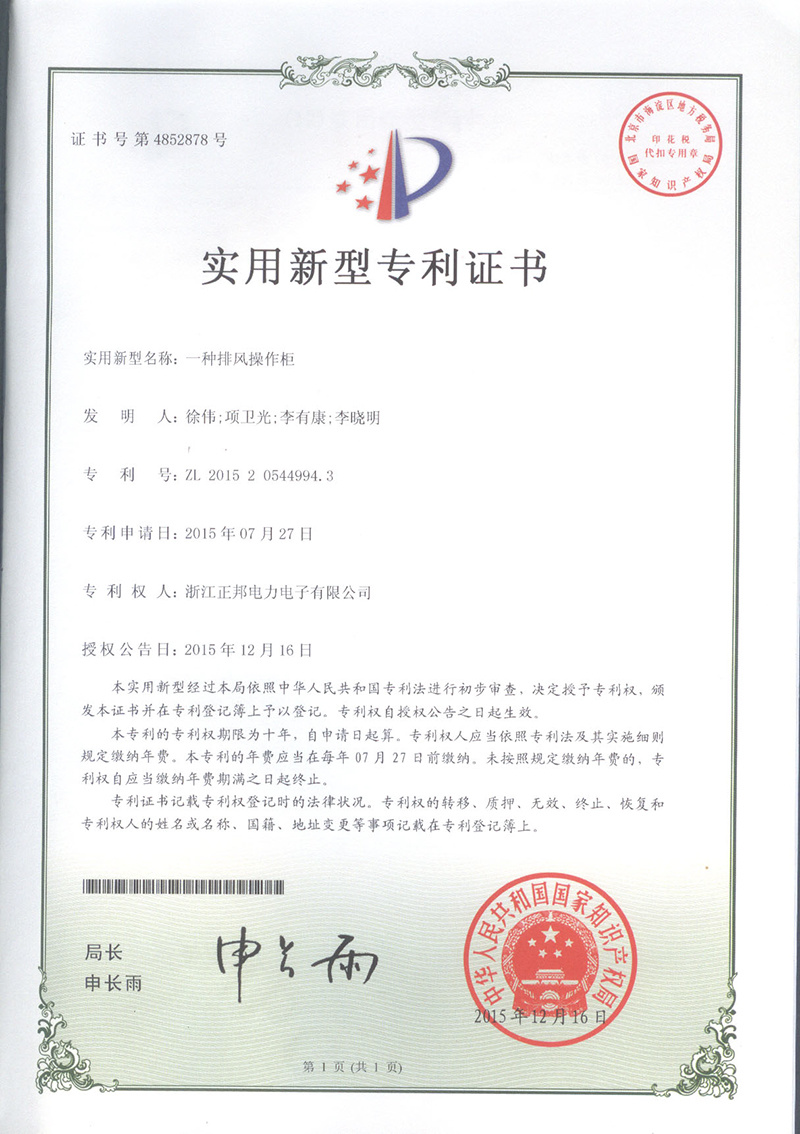

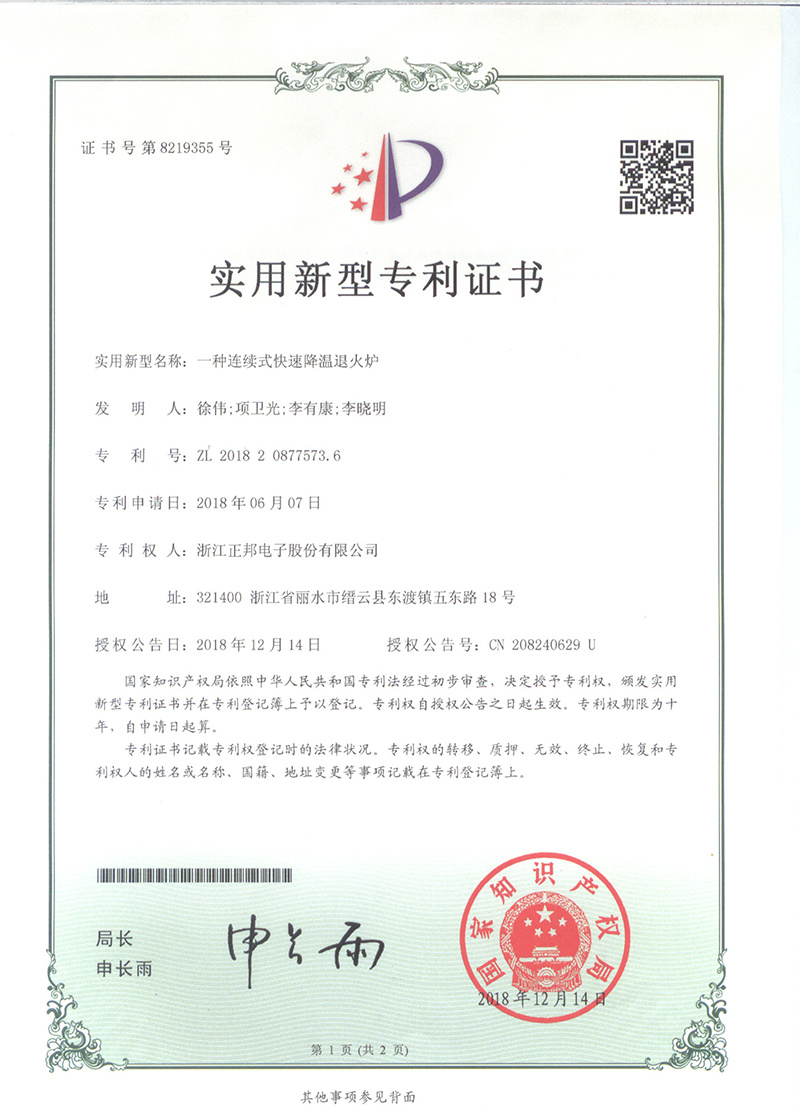

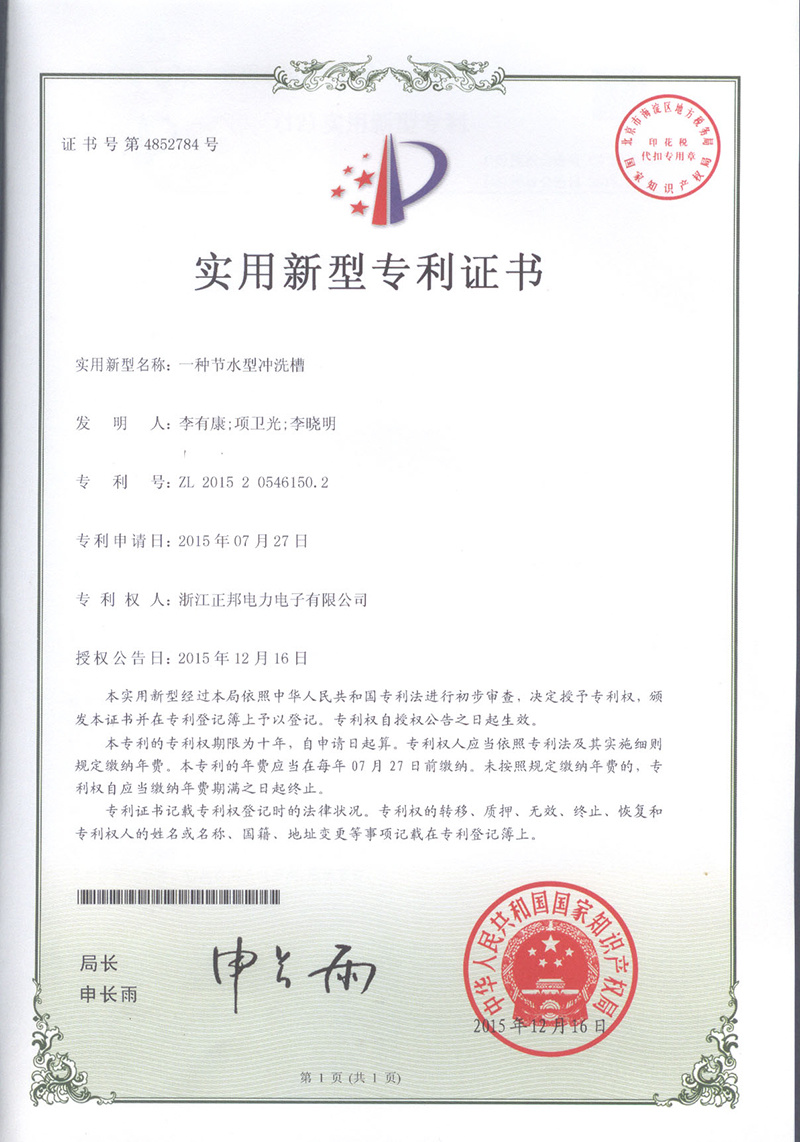

Patent Certificate

Zhengbang Electronics is a national high-tech enterprise, specializing in special new small and medium-sized enterprises in Zhejiang Province, and has good cooperative relations with Huazhong University of Science and Technology, Hangzhou University of Electronic Science and Technology and other universities. the R & D center jointly built with Huazhong University of Science and Technology has been recognized as a provincial innovation carrier by the Provincial Department of Science and Technology, and has established a provincial enterprise research institute, which has made more research and development achievements in recent years.

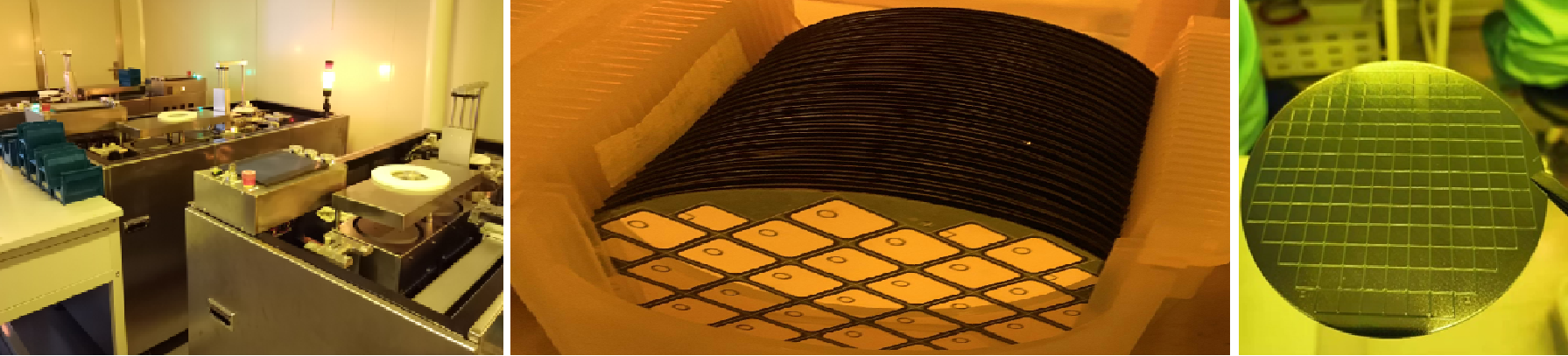

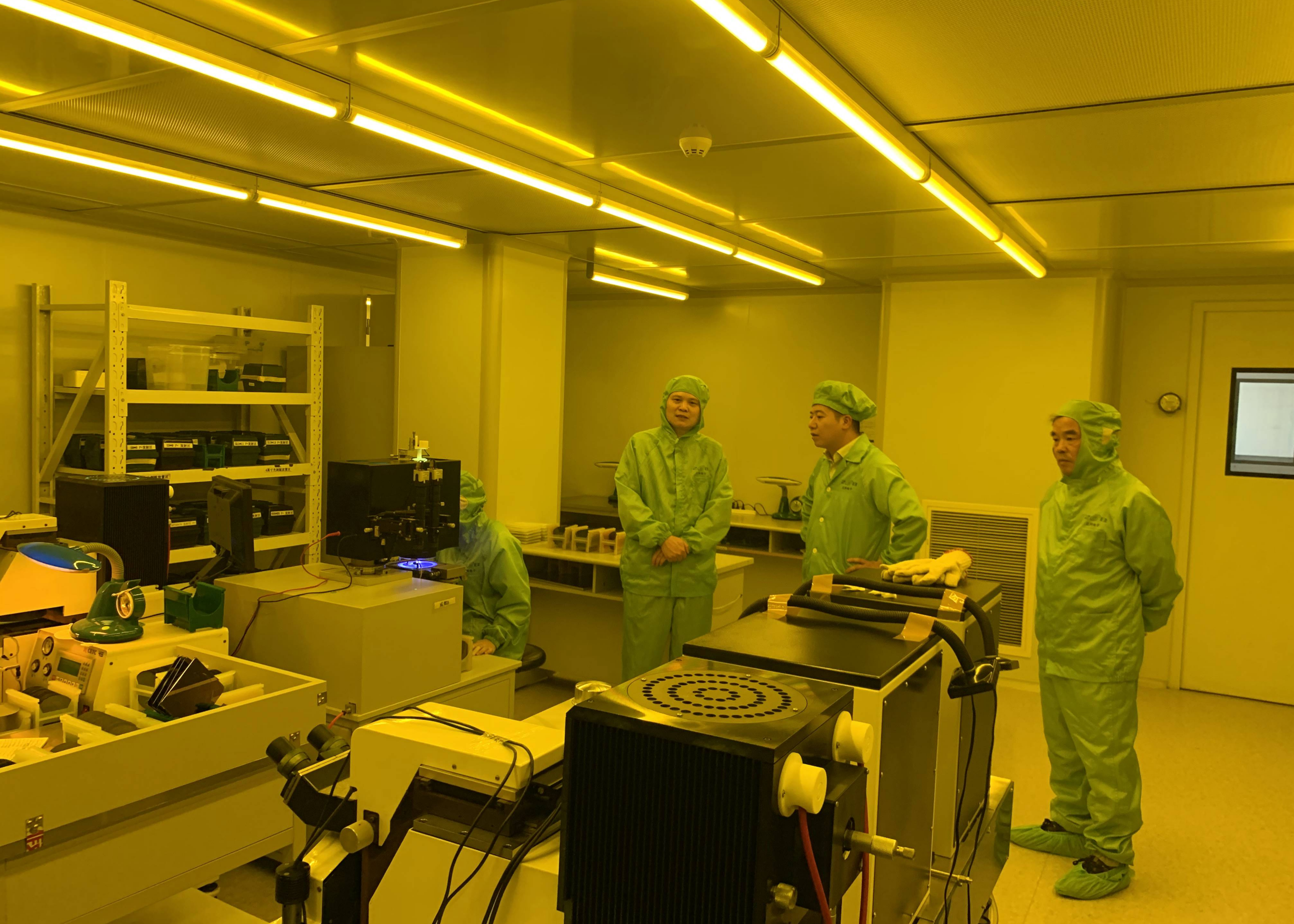

Production line transformation

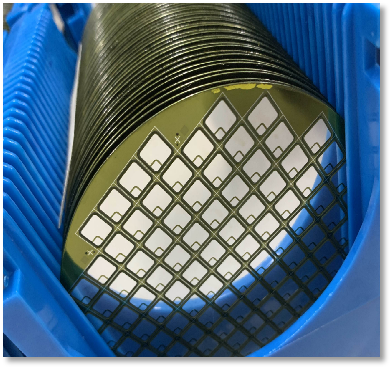

The five-inch production process has been fully adopted to reach the advanced level in the domestic industry. The other chip production line has been comprehensively renovated and upgraded, with more than 1000 square meters of purification plant being rebuilt, the purification level being improved, and advanced production equipment being added to provide a strong guarantee for the production of high-quality and high-reliability chips. Upgrade the diode chip production line, add an automatic acid supply system, and improve the table top processing and production equipment.

New product development

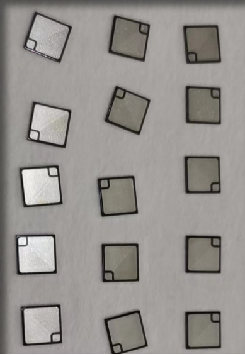

Plastic-encapsulated SCR has been produced in full series from 8A-75A, GPP quick recovery series HER,FR has mass production capacity, and the pilot phase of SF has ended.

KH series high-power high-voltage thyristor chips, GPP series high-voltage glass passivation diode chips, ZTR series chips, ZCR series chips and other series of varieties, and has formed a batch sales.

Application of new technology and new process

Zhengbang Electronics pays attention to technological innovation and continuous improvement. Continuous application of new technologies and new processes in production practice, mainly including: the full use of five-inch chip production process, automatic cleaning of silicon chips before diffusion, automatic gluing of lithography, automatic development of new technologies, plasma etching technology, SI-POS long film technology, silicon wafer surface automatic production of metal electrodes (automatic cleaning and nickel plating), high-efficiency diffusion technology, environmental protection and energy saving automatic photoresist removal technology, silicon wafer automatic coating source, automatic push boat, chip automatic testing and other aspects.